In today’s fast-paced digital world, LED displays have become an essential technology across various industries, from advertising and entertainment to transportation and public information systems. As demand for vibrant, energy-efficient, and versatile display solutions grows, understanding the fundamentals of LED displays and the manufacturing processes behind them is crucial. This article delves into the world of LED displays, exploring their technology, types, applications, and the role of LED display factories in bringing these dynamic screens to life.

Understanding LED Display Technology

LED, or Light Emitting Diode, technology is the backbone of modern digital displays. Unlike traditional display technologies such as LCD or plasma, LED displays use tiny semiconductor diodes that emit light when an electric current passes through them. This fundamental difference offers several advantages, including higher brightness, better contrast, and improved energy efficiency.

At its core, an LED display consists of an array of individual LEDs arranged in a grid. Each LED acts as a pixel or a part of a pixel, capable of producing light in different colors. By controlling the intensity of red, green, and blue LEDs, the display can render a full spectrum of colors, creating vivid images and videos.

One of the key technical aspects of LED displays is the pixel pitch, which refers to the distance between the centers of two adjacent pixels. A smaller pixel pitch results in higher resolution and sharper images, making it suitable for close viewing distances, such as indoor displays. Conversely, larger pixel pitches are often used for outdoor applications where viewers are farther away.

Types of LEDs Used in Displays

LED displays primarily use two types of LEDs: surface-mounted device (SMD) LEDs and through-hole LEDs. SMD LEDs are compact and mounted directly onto the circuit board, allowing for higher pixel density and better color blending. This makes them ideal for indoor displays where high resolution is critical.

Through-hole LEDs, on the other hand, are larger and mounted by inserting their leads through holes in the circuit board. They tend to be more robust and are commonly used in outdoor displays due to their superior brightness and durability under harsh weather conditions.

Advantages of LED Displays

LED displays offer numerous benefits that have propelled their widespread adoption. They provide exceptional brightness levels, often exceeding 5,000 nits for outdoor screens, ensuring clear visibility even in direct sunlight. Their energy efficiency is another significant advantage; LEDs consume less power compared to traditional lighting and display technologies, which translates into lower operating costs.

Durability is also a hallmark of LED displays. They are resistant to shock, vibration, and temperature fluctuations, making them suitable for both indoor and outdoor environments. Additionally, LED displays have a long lifespan, often exceeding 100,000 hours, reducing maintenance and replacement expenses.

The Manufacturing Process of LED Displays

Behind every high-quality LED display lies a complex and precise manufacturing process. LED display factories combine advanced technology, skilled labor, and rigorous quality control to produce displays that meet the demanding requirements of various industries.

Component Sourcing and Quality Control

The manufacturing journey begins with sourcing high-grade components, including LEDs, circuit boards, power supplies, and control systems. LED quality is paramount; factories typically select LEDs from reputable suppliers with consistent brightness, color accuracy, and longevity. Quality control at this stage involves testing LED bins to ensure uniformity and reliability.

Additionally, the printed circuit boards (PCBs) used in LED modules must be designed to optimize heat dissipation and electrical performance. Proper sourcing and inspection of PCBs prevent defects that could compromise the display’s functionality.

Module Assembly and Calibration

Once components are procured, the assembly process begins. LEDs are mounted onto PCBs using automated pick-and-place machines for precision and efficiency. After assembly, LED modules undergo soldering, cleaning, and inspection to ensure all connections are secure and free of defects.

Calibration is a critical step where each LED module is tested for brightness and color uniformity. Advanced measurement tools adjust the output to achieve consistent performance across the entire display. This calibration ensures that the final product delivers uniform images without color shifts or brightness variations.

Panel Integration and Testing

LED modules are then integrated into larger panels or cabinets, which form the building blocks of the final display. These panels include structural frames, power supplies, cooling systems, and control electronics. The design of these components is crucial for the display’s stability, heat management, and ease of installation.

Comprehensive testing follows panel assembly, including stress tests, environmental simulations, and performance evaluations. Factories simulate real-world conditions such as temperature extremes, humidity, and vibration to guarantee durability and reliability. Only after passing these stringent tests are the panels approved for shipment.

Applications of LED Displays Across Industries

LED displays have transformed how information and content are presented in various sectors. Their versatility, scalability, and visual impact make them indispensable tools for communication and advertising.

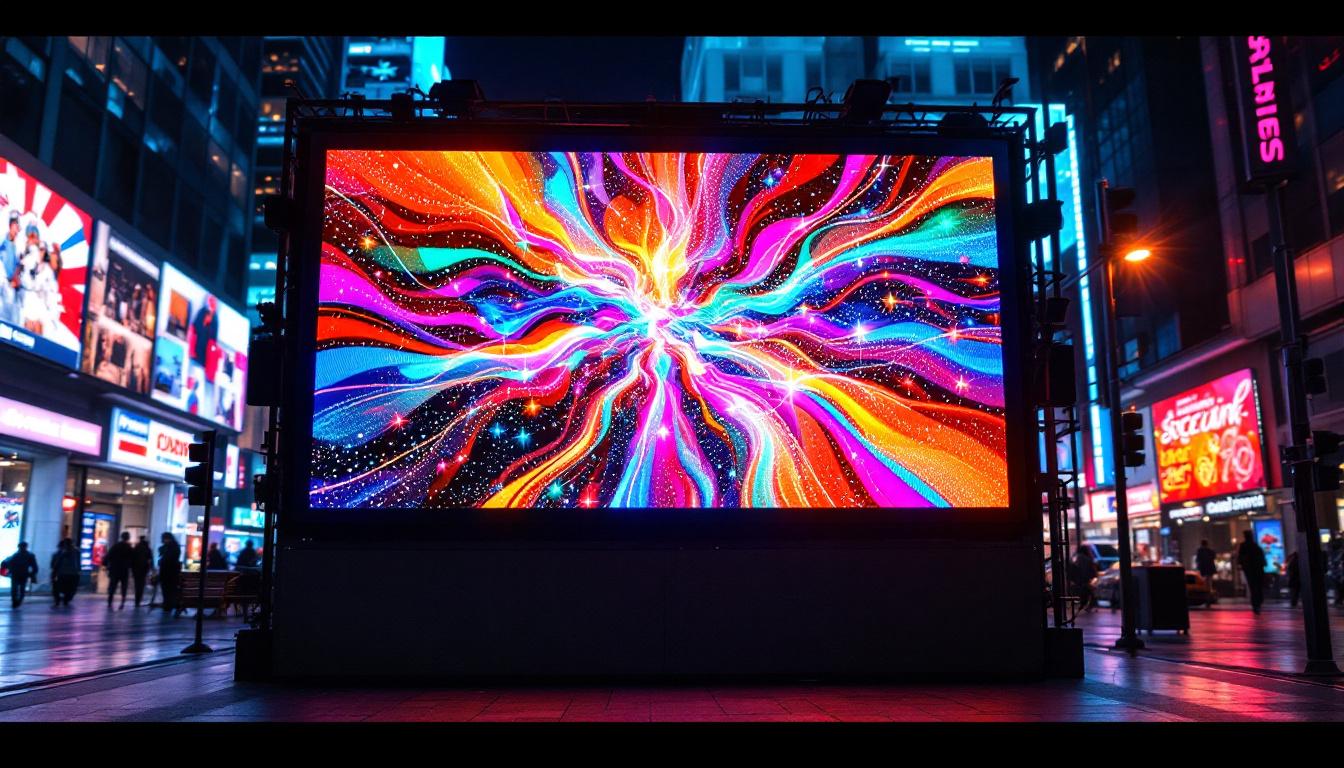

Outdoor Advertising and Digital Billboards

One of the most visible applications of LED displays is in outdoor advertising. Digital billboards equipped with high-brightness LED panels can capture attention day and night. According to the Outdoor Advertising Association of America, digital billboards have seen a 10% annual growth rate over the past five years, driven by their dynamic content capabilities and ability to update messages in real-time.

LED displays allow advertisers to deliver targeted campaigns, rotate multiple ads, and incorporate animations or videos, significantly increasing engagement compared to static billboards. Their weather resistance and long lifespan make them a cost-effective solution for outdoor marketing.

Sports Arenas and Event Venues

Sports arenas and event venues rely heavily on LED displays to enhance the spectator experience. From massive jumbotron screens to perimeter LED strips, these displays provide live scores, replays, advertisements, and interactive content. The ability to customize content instantly makes LED displays invaluable for event organizers and sponsors alike.

Modern stadiums often use high-resolution LED displays with pixel pitches as low as 4mm, ensuring clear visibility even from the stands. The integration of LED technology with broadcast systems also enables seamless content sharing across multiple platforms.

Transportation and Public Information Systems

LED displays play a critical role in transportation hubs such as airports, train stations, and bus terminals. They provide real-time information on schedules, delays, and safety announcements, improving passenger experience and operational efficiency. Their high visibility and reliability are essential in these fast-moving environments.

Urban centers also utilize LED displays for public information, including emergency alerts, weather updates, and community messages. The flexibility to update content remotely allows authorities to communicate effectively with the public in dynamic situations.

Retail and Corporate Environments

In retail, LED displays are used for digital signage, promotional displays, and interactive kiosks. Retailers benefit from the ability to quickly change content to reflect sales, new products, or seasonal campaigns. High-resolution indoor LED displays create immersive brand experiences that attract and retain customers.

Corporate offices employ LED video walls in lobbies, conference rooms, and control centers. These displays facilitate presentations, data visualization, and collaborative work, enhancing communication and decision-making processes.

Choosing the Right LED Display Factory

For businesses and organizations looking to invest in LED display technology, selecting the right manufacturing partner is crucial. A reputable LED display factory can ensure product quality, customization options, and reliable after-sales support.

Evaluating Manufacturing Capabilities

Prospective buyers should assess a factory’s production capacity, technological expertise, and quality control processes. Factories equipped with automated assembly lines, advanced calibration equipment, and rigorous testing protocols are more likely to deliver consistent, high-performance displays.

Experience in producing displays for specific applications is also important. For example, factories specializing in outdoor LED billboards will have expertise in weatherproofing and brightness optimization, while those focused on indoor displays may excel in achieving ultra-fine pixel pitches.

Customization and Innovation

LED display projects often require tailored solutions to meet unique size, shape, and functionality requirements. A factory that offers flexible design options and is open to innovation can provide significant value. This includes the ability to integrate control systems, incorporate touch capabilities, or develop curved and transparent LED displays.

Staying abreast of emerging trends such as MicroLED technology, which promises even higher resolution and energy efficiency, is another indicator of a forward-thinking manufacturer.

After-Sales Service and Support

Reliable after-sales support is essential for maintaining LED displays over their lifespan. This includes technical assistance, warranty coverage, and availability of replacement parts. Factories with established service networks and responsive customer care help minimize downtime and ensure long-term satisfaction.

The Future of LED Display Technology

The LED display industry continues to evolve rapidly, driven by advancements in materials science, manufacturing techniques, and digital content delivery. Emerging technologies promise to expand the capabilities and applications of LED displays even further.

MicroLED and MiniLED Innovations

MicroLED technology involves using microscopic LEDs to create displays with unparalleled brightness, contrast, and energy efficiency. Unlike traditional LEDs, MicroLEDs can achieve pixel pitches below 1mm, enabling ultra-high-definition screens suitable for smartphones, televisions, and augmented reality devices.

MiniLED technology, which uses smaller LEDs than conventional ones but larger than MicroLEDs, offers improved local dimming and contrast for high-end displays. Both technologies are expected to complement existing LED solutions, providing consumers and businesses with more options.

Integration with Smart Technologies

LED displays are increasingly integrated with smart technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and cloud computing. This integration allows for dynamic content management, audience analytics, and interactive experiences. For example, AI-powered LED billboards can adjust advertising content based on real-time demographics and environmental conditions.

Smart LED displays also support remote monitoring and diagnostics, enabling proactive maintenance and reducing operational costs.

Sustainability and Energy Efficiency

As environmental concerns grow, LED display manufacturers are focusing on sustainability. Innovations in LED materials and power management are reducing energy consumption and carbon footprints. Additionally, factories are adopting eco-friendly manufacturing practices, including waste reduction and recycling initiatives.

Energy-efficient LED displays not only benefit the environment but also offer cost savings to users, making them an attractive choice for long-term investments.

Conclusion

LED displays have revolutionized the way information and visuals are presented, offering unmatched brightness, versatility, and durability. Understanding the technology behind these displays and the meticulous manufacturing process helps businesses make informed decisions when selecting LED display solutions.

LED display factories play a pivotal role in ensuring quality, innovation, and reliability. By choosing the right manufacturing partner, organizations can harness the full potential of LED technology to enhance communication, branding, and user engagement across diverse applications.

Looking ahead, advancements such as MicroLED, smart integration, and sustainable practices will continue to drive the evolution of LED displays, making them an indispensable component of the digital landscape for years to come.

Discover Cutting-Edge LED Display Solutions with LumenMatrix

As you consider the future of vibrant and efficient visual communication for your business, LumenMatrix stands at the forefront, ready to illuminate your brand’s message. With a comprehensive range of innovative LED display modules, including Indoor and Outdoor LED Wall Displays, Vehicle LED Displays, LED Poster Displays, LED Sports Displays, Floor LED Displays, Custom LED Displays, All-in-One LED Displays, and LED Transparent Displays, LumenMatrix is committed to revolutionizing the way you connect with your audience. Check out LumenMatrix LED Display Solutions today and experience the transformative power of advanced LED technology tailored to your unique needs.