In the world of technology, precision is key, particularly when it comes to measurements. One common conversion that often arises is that of millimeters to inches. For instance, 0.9 mm is a measurement that can be found in various applications, including LED displays. Understanding this conversion is crucial for designers, engineers, and consumers alike, as it impacts the design and functionality of electronic devices.

The Basics of Measurement Conversion

Measurement conversion is an essential skill that aids in various fields such as engineering, manufacturing, and design. The metric system, which includes millimeters, is widely used around the globe, while the imperial system, which includes inches, is primarily used in the United States. To bridge the gap between these two systems, conversions are necessary.

Understanding Millimeters and Inches

Millimeters (mm) are a unit of length in the metric system, where one millimeter is one-thousandth of a meter. On the other hand, inches are a unit of length in the imperial system, with one inch equating to 2.54 centimeters or 25.4 millimeters. This fundamental difference in measurement systems necessitates conversions, especially in global markets where products are designed and manufactured across different regions.

When dealing with small measurements, such as 0.9 mm, it becomes even more critical to understand the conversion accurately. For example, converting 0.9 mm to inches involves a simple calculation: dividing the millimeter value by 25.4. This results in approximately 0.0354 inches. Such precision is crucial not only for ensuring that components fit together correctly but also for maintaining the integrity of the design throughout the production process. In fields like jewelry making or watch manufacturing, where even the slightest miscalculation can lead to a product that doesn’t function or look as intended, these conversions become a vital part of the workflow.

The Importance of Accurate Measurements

Accurate measurements are vital in various applications, particularly in the design and production of LED displays. A slight deviation in size can lead to significant issues in functionality, aesthetics, and compatibility with other components. For instance, if a designer is working with a specific LED module that requires precise dimensions, converting measurements accurately ensures that the final product meets the intended specifications.

Moreover, when products are sold internationally, having accurate conversions can prevent miscommunication and errors in manufacturing. This is especially true in industries such as electronics, where precision is paramount. In addition to electronics, the construction industry also heavily relies on accurate measurement conversions. Architects and builders must ensure that blueprints and physical materials align perfectly, as even a minor error can result in structural issues or safety hazards. Furthermore, the rise of online shopping has increased the need for clear and accurate product descriptions, including dimensions, to cater to a global audience. Customers expect to receive products that match their expectations based on the measurements provided, making it imperative for businesses to get these conversions right.

LED Displays: An Overview

LED (Light Emitting Diode) displays have become increasingly popular due to their brightness, energy efficiency, and versatility. They are used in a wide range of applications, from televisions and computer monitors to signage and lighting solutions. Understanding the specifications of LED displays, including size and resolution, is crucial for optimal performance.

What Makes LED Displays Unique?

LED displays operate by using an array of tiny light-emitting diodes to produce images. Unlike traditional LCD screens, which rely on backlighting, LED displays emit their own light, resulting in brighter colors and deeper blacks. This technology allows for thinner designs and improved energy efficiency.

Furthermore, LED displays can be easily scaled to different sizes, making them suitable for various applications. Whether it’s a small screen for a handheld device or a large billboard, the flexibility of LED technology is a significant advantage. Additionally, advancements in LED technology have led to the development of OLED (Organic Light Emitting Diode) displays, which offer even greater contrast ratios and color accuracy, further enhancing the viewing experience. As a result, consumers are increasingly drawn to these displays for both personal and professional use, as they provide a more immersive visual experience.

Key Specifications of LED Displays

When evaluating LED displays, several key specifications come into play. These include pixel pitch, resolution, brightness, and size. Pixel pitch refers to the distance between the centers of two adjacent pixels, which directly impacts the display’s clarity and detail. A smaller pixel pitch results in a higher resolution, making it ideal for close viewing distances.

Brightness, measured in nits, indicates how well the display performs in various lighting conditions. Higher brightness levels ensure visibility in bright environments, such as outdoors. Lastly, the physical size of the display, often measured in inches, is crucial for determining how the display will fit into a given space. In addition to these specifications, color gamut is another important factor, as it defines the range of colors that the display can reproduce. A wider color gamut allows for more vibrant and lifelike images, which is particularly important for applications in graphic design and video production. Moreover, refresh rate, measured in hertz (Hz), plays a critical role in how smoothly motion is rendered on the screen, making it a vital specification for gamers and those who watch fast-paced content.

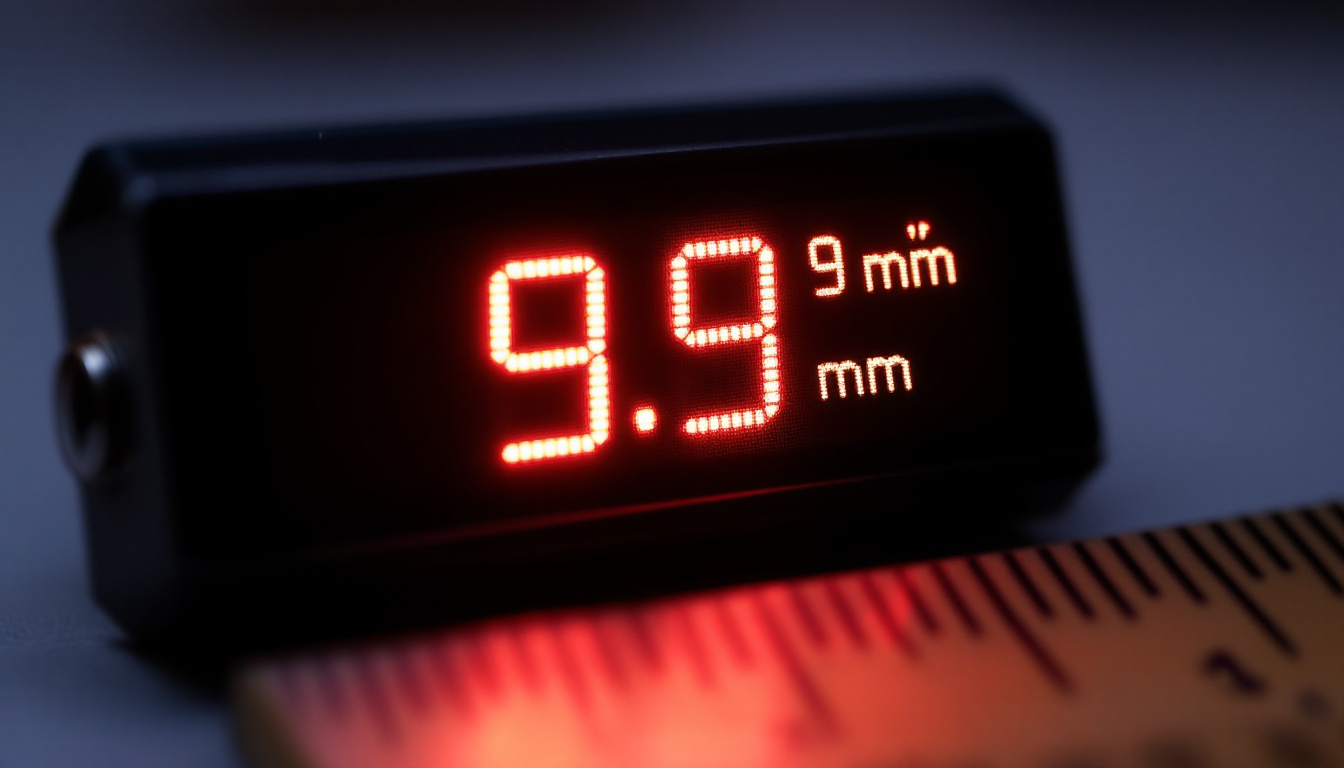

Converting 0.9 mm to Inches in LED Displays

When designing or selecting LED displays, understanding the dimensions involved is critical. As previously mentioned, 0.9 mm converts to approximately 0.0354 inches. This small measurement can have a significant impact on the overall design and functionality of the display.

Why 0.9 mm Matters in Display Design

In the context of LED displays, 0.9 mm can refer to the pixel pitch or the spacing between diodes. A pixel pitch of 0.9 mm is considered high resolution, suitable for applications where clarity and detail are paramount. This is particularly important in environments such as control rooms, broadcasting studios, or retail displays, where viewers are often close to the screen.

Choosing a display with a pixel pitch of 0.9 mm ensures that the images produced are sharp and vibrant, enhancing the viewer’s experience. In contrast, a larger pixel pitch may result in a grainy appearance, especially when viewed up close.

Applications of 0.9 mm LED Displays

LED displays with a pixel pitch of 0.9 mm find applications in various sectors. In the corporate world, they are used for digital signage, presentations, and video walls. The high resolution allows for clear visibility of text and graphics, making them ideal for conveying information effectively.

In the entertainment industry, 0.9 mm LED displays are often used in concert venues and theaters, where high-quality visuals are essential. Additionally, they are increasingly being utilized in retail environments to attract customers with vibrant advertisements and promotions.

Challenges and Considerations in LED Display Design

While the advantages of LED displays are numerous, there are also challenges that designers and manufacturers must consider. These challenges can impact the overall performance and longevity of the display.

Heat Management

One of the primary challenges faced by LED displays is heat management. LEDs generate heat during operation, and excessive heat can lead to reduced performance and lifespan. Effective heat dissipation techniques, such as heat sinks and fans, are essential to maintain optimal operating temperatures.

Designers must also consider the materials used in the display’s construction, as some materials may not withstand high temperatures. Ensuring that the display remains within safe temperature limits is crucial for reliability and longevity.

Color Calibration

Color accuracy is another critical aspect of LED display design. Variations in color output can occur due to differences in manufacturing processes or aging of the diodes. Regular calibration is necessary to ensure consistent color representation across the display.

Advanced calibration techniques, including software-based solutions, can help maintain color fidelity. This is particularly important in applications where color accuracy is paramount, such as in graphic design or photography.

The Future of LED Display Technology

The LED display industry continues to evolve, with advancements in technology paving the way for even more innovative solutions. As demand for high-quality displays increases, manufacturers are investing in research and development to enhance performance and reduce costs.

Emerging Trends in LED Displays

One of the most notable trends is the development of flexible and transparent LED displays. These displays can be integrated into various surfaces, such as windows and walls, creating new opportunities for advertising and design. The ability to bend and shape displays opens up a world of possibilities for creative applications.

Additionally, advancements in microLED technology are set to revolutionize the industry. MicroLEDs are smaller than traditional LEDs, allowing for even higher pixel densities and improved performance. This technology promises to deliver stunning visuals with enhanced brightness and energy efficiency.

Environmental Considerations

As sustainability becomes a priority in all industries, the LED display sector is also focusing on reducing its environmental impact. Manufacturers are exploring eco-friendly materials and production processes to minimize waste and energy consumption.

Furthermore, the longevity of LED displays contributes to sustainability efforts, as longer-lasting products reduce the need for frequent replacements. This not only benefits the environment but also provides cost savings for consumers and businesses alike.

Conclusion

Understanding the conversion of 0.9 mm to inches is essential for anyone involved in the design or selection of LED displays. This small measurement can significantly impact the performance and quality of a display, making accurate conversions crucial.

As technology continues to advance, LED displays are becoming more versatile and efficient, paving the way for innovative applications across various industries. By keeping abreast of measurement conversions and emerging trends, designers and consumers can make informed decisions that enhance their projects and experiences.

In summary, the world of LED displays is dynamic and ever-evolving, with the potential for exciting developments in the future. By understanding the importance of precise measurements and staying informed about industry trends, stakeholders can ensure they are well-equipped to navigate this rapidly changing landscape.

Discover Cutting-Edge LED Display Technology with LumenMatrix

Ready to experience the future of visual communication? LumenMatrix is at the forefront of LED display innovation, offering a wide array of solutions designed to captivate and engage. From Indoor and Outdoor LED Wall Displays to specialized options like Vehicle, Sports, and Floor LED Displays, our products are crafted to transform your space and message into an unforgettable visual journey. Whether you’re looking to create custom LED displays or seeking an All-in-One solution, LumenMatrix has the technology to bring your vision to life. Don’t miss out on the opportunity to elevate your brand’s visibility with our LED Transparent Displays and more. Check out LumenMatrix LED Display Solutions today and join the revolution in LED display technology.