Screen printing remains one of the most versatile and widely used methods for applying designs to a variety of surfaces, from textiles to electronics. Among its many applications, the creation of custom screens for LED displays is a specialized area that combines traditional printing techniques with modern technology. This article delves into the intricacies of screen printing custom screens specifically for LED displays, explaining the technology, processes, and benefits involved.

Understanding LED Displays and Their Significance

LED (Light Emitting Diode) displays have revolutionized the way information and visuals are presented in public and private spaces. From massive outdoor billboards to indoor digital signage, LED displays offer bright, energy-efficient, and highly customizable solutions. According to market research, the global LED display market is expected to reach over $30 billion by 2027, driven by increasing demand for digital advertising and smart city infrastructure. The versatility of LED technology has also led to its adoption in various sectors, including entertainment, retail, transportation, and even healthcare, where dynamic displays can enhance communication and engagement.

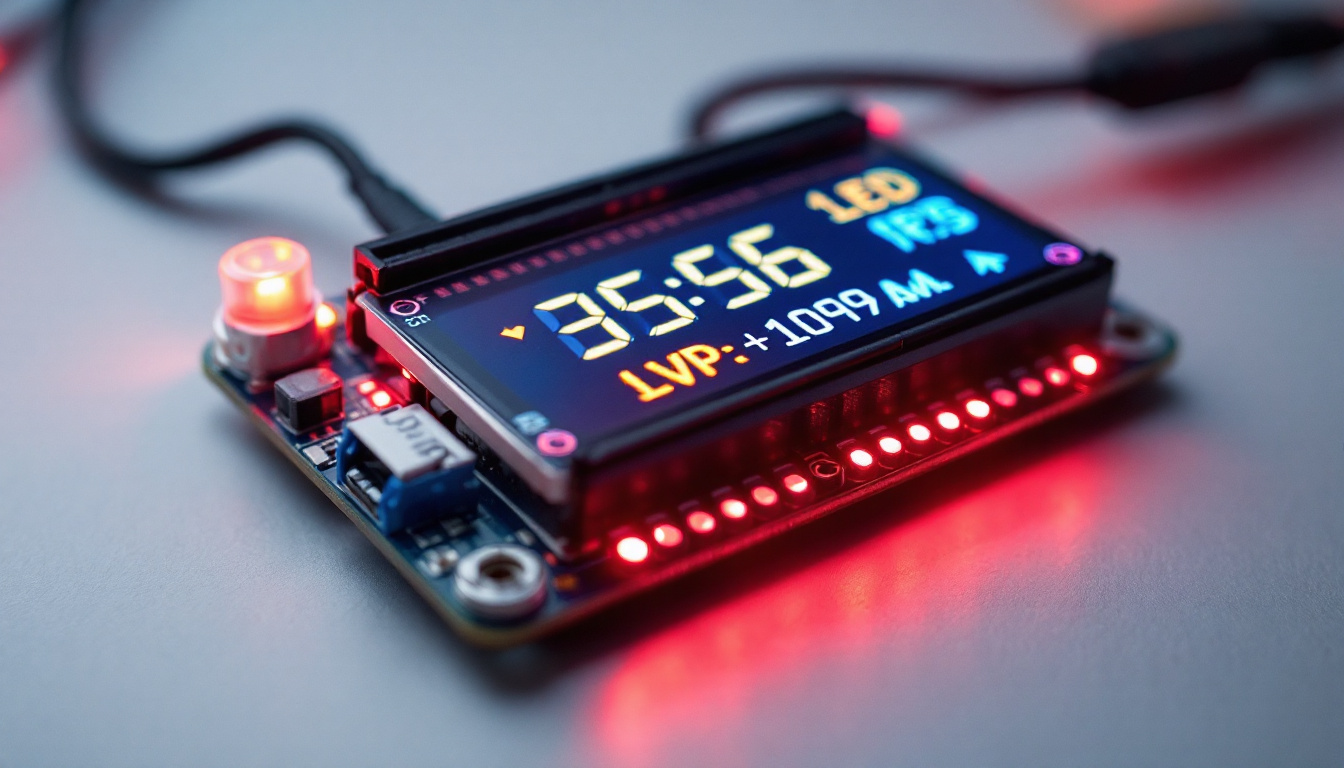

LED displays consist of numerous tiny LEDs arranged in a matrix, which can be individually controlled to display images, videos, or text. The quality and clarity of these displays depend heavily on the precision of the underlying components, including the printed circuits and screens that support the LEDs. The advancements in LED technology, such as the development of micro-LED and mini-LED displays, have further improved brightness, color accuracy, and energy efficiency, making them even more appealing for high-end applications such as televisions and gaming monitors.

The Role of Screen Printing in LED Display Manufacturing

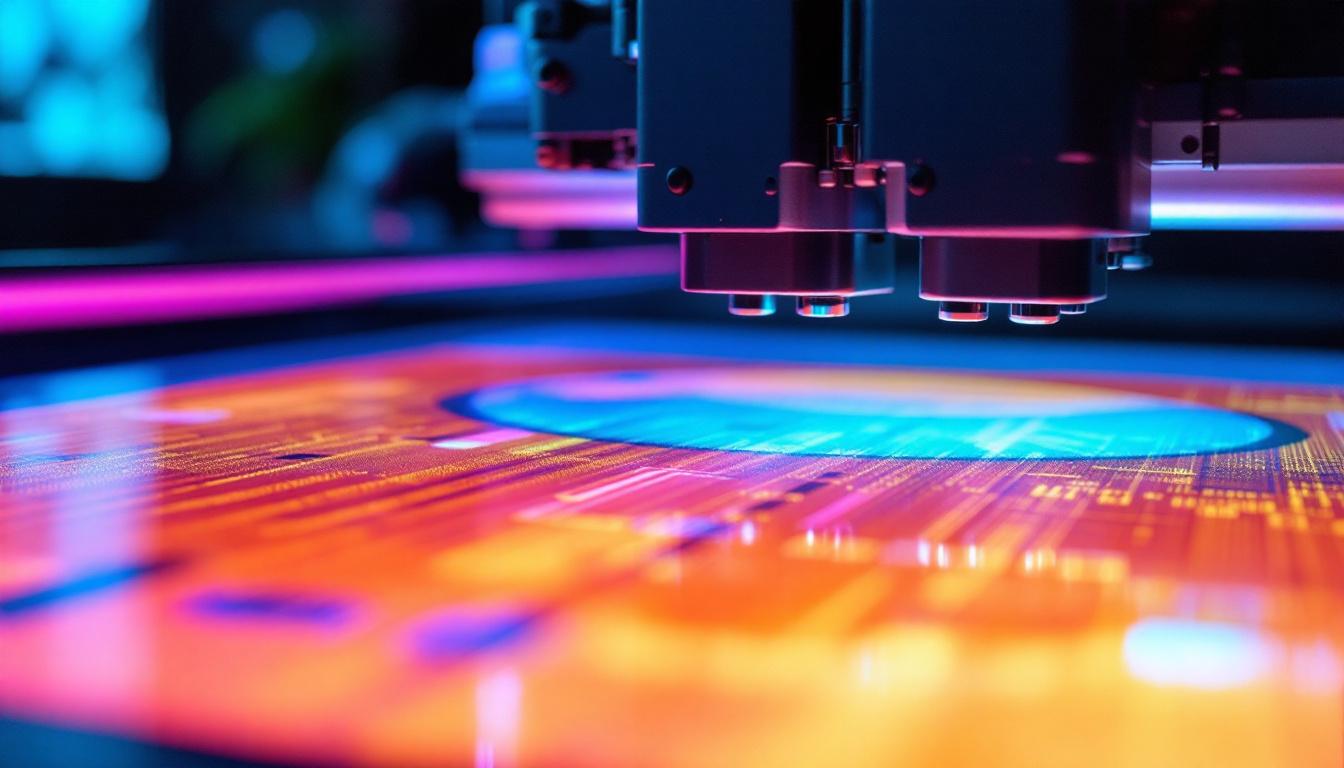

Screen printing plays a critical role in the manufacturing of LED displays, particularly in the production of custom screens that serve as the foundation for LED placement and circuitry. The process involves transferring ink or conductive materials through a mesh stencil onto a substrate, creating precise patterns necessary for electrical connectivity and light diffusion. This technique not only ensures that the LEDs are correctly aligned but also enhances the overall aesthetic appeal of the display by allowing for intricate designs and vibrant colors.

Custom screens are essential because each LED display may require a unique pattern depending on its resolution, size, and application. For example, a high-resolution indoor display demands finer screen meshes and more intricate printing compared to a large outdoor billboard. Additionally, the choice of inks and materials used in screen printing can significantly impact the durability and longevity of the display. Innovations in eco-friendly inks and substrates are also gaining traction, aligning with the growing emphasis on sustainability in manufacturing processes. As the demand for LED displays continues to rise, the importance of high-quality screen printing techniques will remain a cornerstone of effective and innovative display solutions.

Screen Printing Custom Screens: The Process Explained

Creating custom screens for LED displays through screen printing involves several detailed steps, each crucial to ensuring the final product meets technical and aesthetic standards.

1. Design and Pattern Preparation

The first step in screen printing custom LED screens is designing the pattern. This pattern dictates where conductive inks or other materials will be deposited to form circuits or light guides. Designers use specialized software to create high-precision vector files that correspond to the LED layout and electrical requirements.

Accuracy at this stage is paramount. Even minor deviations can lead to faulty connections or uneven lighting, which compromises the display’s performance. Designers often collaborate closely with engineers to ensure the pattern meets electrical and mechanical specifications.

2. Screen Fabrication

Once the design is finalized, the next step is fabricating the screen itself. This involves coating a fine mesh screen—typically made of polyester or stainless steel—with a light-sensitive emulsion. The prepared design is then transferred onto the emulsion-coated screen using a UV exposure process.

During exposure, the emulsion hardens in the areas not covered by the design, while the covered areas remain soft and are washed away, creating a stencil. This stencil allows ink to pass through only in the desired pattern during printing.

3. Ink Selection and Preparation

For LED display applications, the choice of ink is critical. Conductive inks, often containing silver or carbon particles, are commonly used to create electrical pathways. Additionally, inks with specific optical properties may be used to enhance light diffusion or color accuracy.

Ink formulation must ensure strong adhesion to the substrate, durability under environmental stresses, and compatibility with the screen printing process. Manufacturers often customize ink blends to meet the unique requirements of each LED display project.

4. Printing and Curing

With the screen and inks ready, the printing process begins. The screen is placed over the substrate—usually a flexible or rigid circuit board—and ink is pushed through the stencil using a squeegee. The precision of this step determines the clarity and functionality of the printed circuits.

After printing, the ink must be cured to solidify and adhere properly. Curing methods vary but often include thermal ovens, UV light exposure, or infrared heating. Proper curing ensures the printed patterns maintain conductivity and resist wear over time.

5. Quality Control and Testing

Given the critical nature of LED display components, rigorous quality control is essential. Printed screens undergo visual inspection, electrical testing, and sometimes microscopic analysis to detect defects such as incomplete prints, misalignments, or ink inconsistencies.

Functional testing may involve applying voltage to the printed circuits to verify conductivity and continuity. This step helps prevent costly failures in the final LED display assembly.

Advantages of Using Screen Printing for Custom LED Screens

Screen printing offers several distinct advantages when producing custom screens for LED displays, making it a preferred method in the industry.

High Precision and Customization

Screen printing allows for the creation of highly detailed and precise patterns, essential for the complex circuitry of LED displays. The ability to customize each screen to specific design requirements enables manufacturers to produce displays tailored to diverse applications, from small wearable devices to large-scale advertising panels.

Cost-Effectiveness for Large-Scale Production

While initial setup costs for screen printing can be significant due to screen fabrication and design preparation, the process becomes highly cost-effective for large production runs. The reuse of screens and the speed of printing reduce per-unit costs, making it ideal for mass manufacturing of LED display components.

Material Versatility

Screen printing supports a wide range of inks and substrates, allowing manufacturers to experiment with different materials to optimize performance. Whether printing on flexible circuits for curved displays or rigid boards for outdoor signage, screen printing adapts well to various materials.

Durability and Reliability

Printed circuits produced via screen printing exhibit strong adhesion and resistance to environmental factors such as moisture, temperature fluctuations, and mechanical stress. This durability is crucial for LED displays exposed to outdoor conditions or continuous operation.

Challenges and Considerations in Screen Printing for LED Displays

Despite its advantages, screen printing custom screens for LED displays involves challenges that manufacturers must carefully manage.

Maintaining Fine Resolution

As LED displays advance towards higher resolutions, the demand for finer printed patterns increases. Achieving this requires extremely fine mesh screens and precise control over ink viscosity and printing parameters. Any inconsistency can lead to blurred or incomplete circuits.

Ink Conductivity and Longevity

Conductive inks must maintain their electrical properties over the lifespan of the display. Factors such as oxidation, mechanical wear, and thermal cycling can degrade conductivity. Selecting and formulating inks that withstand these conditions is a complex task requiring ongoing research and testing.

Environmental and Safety Concerns

Some conductive inks contain heavy metals like silver or other potentially hazardous materials. Manufacturers must comply with environmental regulations and implement safe handling and disposal practices to minimize ecological impact.

Integration with Other Manufacturing Processes

Screen printing is often one part of a multi-step manufacturing process for LED displays. Coordinating screen printing with other processes such as pick-and-place LED assembly, encapsulation, and testing requires precise timing and quality alignment to ensure seamless production.

Future Trends in Screen Printing for LED Displays

The screen printing industry is evolving alongside advances in LED technology, promising exciting developments in custom screen production.

Emergence of Printed Electronics

Printed electronics, which use screen printing to create entire electronic circuits on flexible substrates, are gaining traction. This approach enables thinner, lighter, and more flexible LED displays, opening new applications in wearable technology, automotive interiors, and smart packaging.

Advancements in Conductive Inks

Researchers are developing new conductive inks with improved conductivity, environmental friendliness, and mechanical flexibility. Innovations include nano-silver inks, graphene-based inks, and conductive polymers that could enhance the performance and sustainability of printed LED circuits.

Automation and Digital Integration

Automation in screen printing, including robotic handling and digital patterning, is increasing production speed and accuracy. Digital screen printing techniques, which eliminate some traditional steps, are also emerging, offering greater flexibility for short runs and rapid prototyping.

Conclusion

Screen printing custom screens for LED displays is a sophisticated process that bridges traditional printing methods with cutting-edge electronic manufacturing. Its ability to produce precise, durable, and customizable patterns makes it indispensable in the LED display industry. As technology advances, the integration of screen printing with new materials and digital techniques promises to further enhance the capabilities and applications of LED displays worldwide.

For manufacturers and designers, understanding the nuances of screen printing custom screens is essential to harnessing the full potential of LED technology. With ongoing innovation and careful process management, screen printing will continue to play a pivotal role in the future of digital displays.

Discover LumenMatrix’s Advanced LED Display Solutions

Ready to elevate your visual communication with high-precision, customizable LED displays? Explore LumenMatrix’s innovative range of LED display modules, designed to captivate your audience and amplify your message. From vibrant Indoor LED Walls to dynamic Outdoor LED Displays, and from sleek LED Posters to immersive Floor LED Displays, LumenMatrix has the perfect solution to meet your needs. Embrace the future of digital signage with LumenMatrix and create experiences that resonate. Check out LumenMatrix LED Display Solutions today and see your vision come to life.